Equipment

Composite Manufacturing:

Our facility features a 30 sq. ft. walk-in curing oven and a 6 sq. ft. lab oven, allowing

us to cure prepreg composite materials with precision. These ovens transform soft,

pliable prepregs into rigid, high-strength components with superior structural integrity.

Injection Molding

Our Plastics department features a BabyPlast injection molding machine paired with

a Mortto dryer, serving as the introductory step for small-production molding. Additionally,

students gain hands-on experience with industry-standard Nissei 50-ton and Boy 22-ton

machines, working with both analog and digital controls.

We provide high-efficiency chillers designed specifically to cool injection molds.

Our systems use internal cooling channels to rapidly dissipate the heat generated

by molten plastics, protecting your equipment and reducing production downtime.

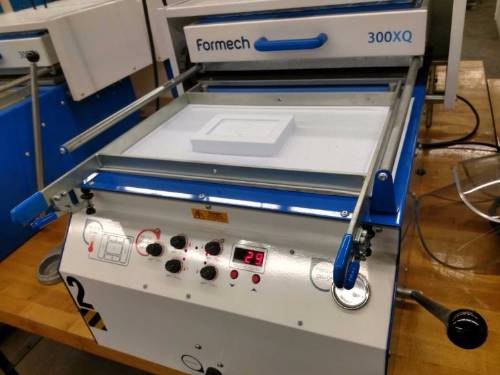

Thermoforming

We utilize an industrial-grade Formech vacuum former as a cornerstone of our Plastics

Manufacturing curriculum. This equipment allows for the fast, cost-effective creation

of complex three-dimensional shapes.

Extruding

Our lab features the Filabot Airpath, a specialized cooling system that uses forced

air to stabilize filament as it’s extruded. This system works in tandem with the Filabot

Spooler to provide easier setups and greater precision for common materials like ABS

and PLA. It is especially critical for research involving high-temperature polymers,

where controlled cooling is necessary before spooling. With integrated speed monitoring,

students and researchers can maintain the perfect consistency for every batch.

Molding Machines

Our lab is equipped with multiple rotational machines to support a variety of manufacturing

techniques. We feature the Power Lab #812

for high-quality hot rotational molding, as well as the BJB CPE 615 Rotational Casting

Machine, specifically designed for processing two-part plastics like urethane.

Our lab features a Carver Inc. compression molding press, engineered for high-precision

material processing. This system is equipped with advanced heating and cooling platens

managed by a programmable digital controller. With independent thermal loops for each

platen and customizable cooling programs, students can achieve the exact cooling rates

required for professional-grade results.

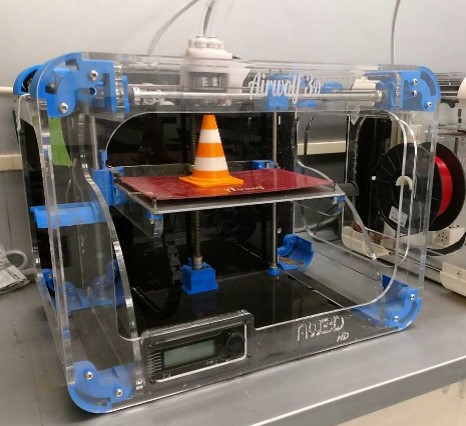

3D Printing

Our lab is equipped with multiple Airwolf 3D printers, allowing students to seamlessly

transition from digital design to physical reality. These machines translate complex

CAD data into high-precision, three-dimensional parts, providing a cornerstone for

our additive manufacturing curriculum.

Testing Equipment

Our Stuart melting point apparatus features digital temperature selection, measurement,

and display, ensuring precise results and eliminating the need for a traditional thermometer.

Large Fabrication Equipment